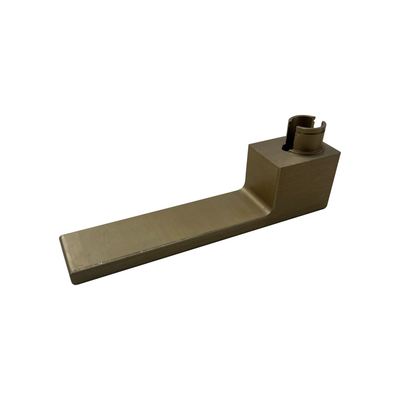

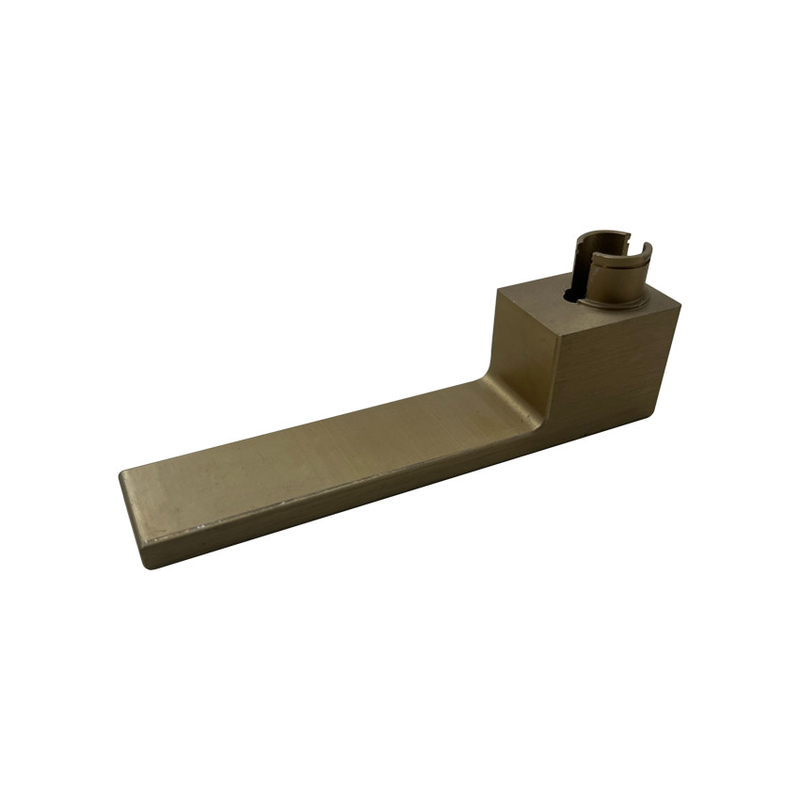

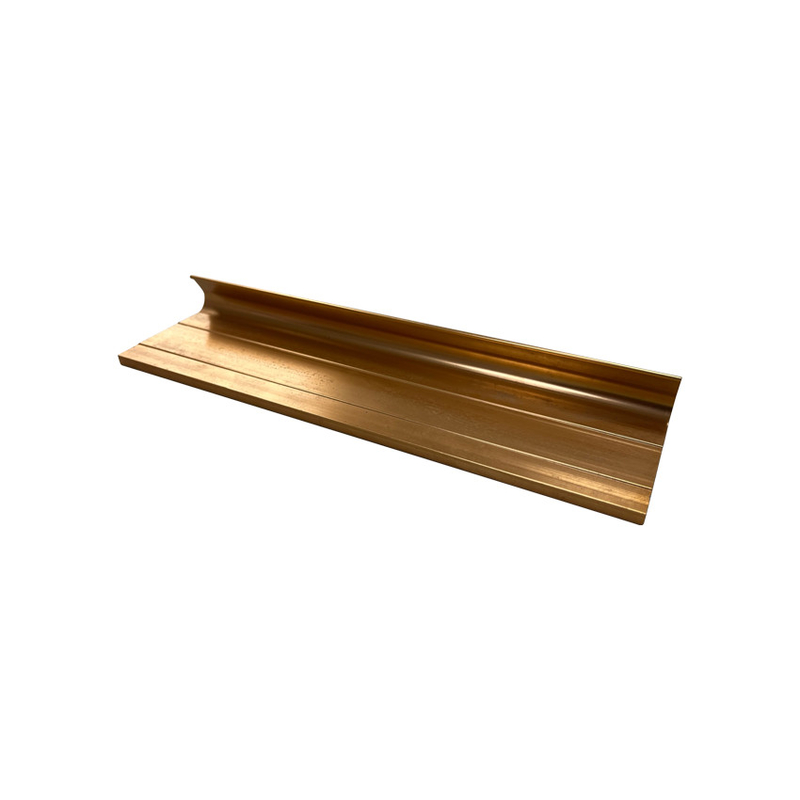

High Precision Metal Stamping Parts Custom Aluminum Sheet Metal Fabrication

Product Description

1.Over 10 years exerience in metal stamping parts

2.Facility: Stamping machines, automatic stamping machine, punching machines, Oil Hydraulic pressing machines, bending machines, welding machines, meter lathes

3.Standard: OEM manufacturing as per customers requirements.

4.Key words: sheet metal fabrication/ metal component/ sheet metal processing/ metal stamping parts

Specification

|

|

Custom made metalwork laser cutting service aluminum stainless steel parts stamping bending sheet metal fabrication

|

|

Materials

|

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc.

Other Special Materials:Lucite/Nylon/wood/titanium/etc

|

|

Surface Treatment

|

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc

|

|

Tolerance

|

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

|

|

Testing equipment

|

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement

|

|

Processing

|

CNC turning, CNC milling, CNC machining, Grinding, EDM wire cutting

|

|

File Formats

|

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc.

|

|

Service Project

|

To provide production design, production and technical service, mould development and processing, etc

|

FAQ

Q1:Where can I get product&price information?

A1:Send us e-mail , we will contact you as we receive your mail.

Q2: How soon can I get samples?

A2: Depending on your specific project, it usually takes 10 to 20 days.

Q3:How to enjoy the OEM services?

A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q4:Can you make machining parts based on our samples?

A4:Yes, we can make measurement based on your samples to make drawings for machining parts making.

Q5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

.